What Is Logistics Management?

Logistics management is often described as both an art and a science — it is the integration of the interconnected processes and movements that take a product from its origin all the way to end user delivery. The process incorporates numerous partners and systems, and it sets the foundation that allows the supply chain to transform raw materials into finished goods. Ideally, the activities of logistics management should be almost invisible to the end user.

The entire logistics management process encompasses the functions of inbound logistics, which includes acquisition, transportation, and storage of the raw materials, information, and support needed to develop a new product or service. Outbound logistics takes that new product/service and provides the support and process to deliver it into the hands of the end user. In between, many other utilities support these main functions, including the following:

- Sourcing/procurement/purchasing/supplier logistics

- Reverse and green logistics

- Production planning/construction logistics

- Inventory and warehousing logistics

- Transportation logistics: Global/customs and domestic

The processes that comprise the logistics network can be integrated and adapted to support the day-to-day functions of numerous industries and organizations. They can also be formulated and deployed for short-term or situational needs, such as in response to natural or man-made emergencies.

There are many moving parts to a logistics management program, and when they work in harmony, they can strongly support cost and efficiency optimization. This is where today’s information technology automation and frameworks can make a difference for large-scale logistic initiatives.

For example, transportation and warehousing are two integral elements of logistics. As such, they get the most attention by service providers. Fleets and freight management select the best transportation routes and services, whether sea, air, rail, road, or a combination. Time-zone and border issues affect scheduling, planning, and packaging as well. To keep track of inventories, floor capacity, and storage — of both inbound resources and outbound products — organizations must carefully schedule, handle, and manage people, equipment, data, and processes. Other departments may be called on to assist too. To coordinate these disparate functions and stay atop of the communication between all parties, companies need effective information collection and automation systems.

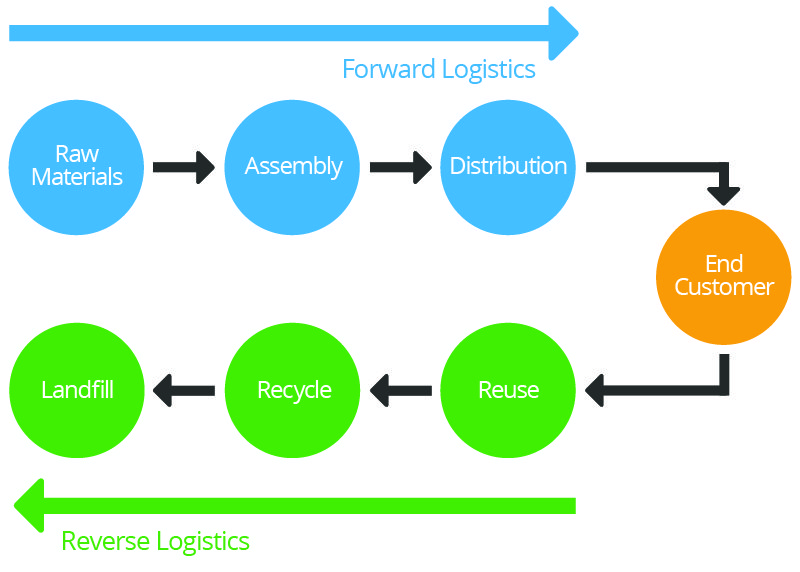

The Difference Between Forward and Reverse Logistics

It's fairly easy to see how the continuous, timely, and careful forward movement of materials, information, and services are critical to successful logistics management. Forward logistics has both inbound and outbound processes that follow a product from origin to the user. However, there are situations in which is it equally as important to manage surpluses, leftovers, or damaged supplies and equipment.

The reverse logistics process deals with discerning or recapturing value from leftover inventory or material, including returns to vendors and supplies marked for reuse, as well as those set for proper disposal. Reverse logistics also supports emerging green logistics initiatives that minimize negative impacts from ecological destruction. In addition, reuse, effective return, or repurposing of goods provides the beneficial economic efficiencies that lead to a positive bottom line.

What Is Logistics in a Business?

In the military, battlefield readiness and success often hinge on a properly managed supply line. While the stakes and outcomes may be quite different in the civilian world, business logistics — the coordinated effort to move a product from origin to end user — has many of the same complexities and tactical elements.

The term business logistics entered into general use in the 1960s to describe the seamless integration of activities that enable movement through the entire supply chain.

Careful management of the inbound and outbound movement of materials and product is an integral part of the overall success of the business. Any hiccup in these movements can be costly and disruptive, impacting productivity, profitability, and customer perception.

What Is the Meaning of International Logistics?

International logistics adds another layer of complexity to business logistics. It accounts for differences across global jurisdictions, including unique laws and customs of a region or country, as well as changing environments or governments. International logistics must also weigh additional information regarding packaging and transport, such as long-haul freight arrangements, time-zone challenges, quarantine issues, duties, taxes, tariffs, and customs clearance.

Tools and Solutions Used for Logistics Management

An effective ERP system could already have many of the elements necessary to support the optimized flow of materials and information for a logistics system, but you may need specialized software or automation tools, too.

- Materials Management: A materials management solution may aid in qualifying vendors, buying, paying for, and housing materials, and identifying location and quantity.

- Inventory Flow: Tools and frameworks that manage inventory flow — including demand forecasting, equipment usage, picking procedures, SKU/order processing, parts and services support, and capacity flow — provide the visibility, access, and balance that can contain costs and eliminate shortages.

- Transport Automation: Tools and software that support transportation, which represent a large component of the movement of product, can handle fleet maintenance and management (as well as costs and time constraints associated with downed vehicles), mitigate increased fuel costs, or identify bad habits by key personnel.

These tools can provide real-time information that keeps a production line on schedule and allows for quick adjustments when necessary. Benefits may include reduced costs, improved communication, and improved workflow/project life cycles.

Systems and services to aid in logistics management are available from numerous providers, including SAP, Ruptela, Ingenics, GlobalTranz, Accenture, Anderson Consulting, and Cerasis.

Outsourcing Logistics Management

As business and technology become more complex, many organizations take advantage of the expertise available from outsourced providers to handle logistics management. Outsourcing arrangements can cover a single contract for providing services as-needed, the development of joint ventures, or spinning off a part of the business to focus on logistics initiatives. Third-party logistics providers (3PL) can offer single-use solutions or take on elements of the logistics structure. Transportation is often a prime candidate for outsourcing, as it’s one of the most complex elements of logistics management.

Some organizations may find that they are best served by more robust strategic partnerships, especially where there are gaps in technology or in multiple aspects of logistics. With this approach, the development of strong relationships and good communication is key. If the partners have built trust, a fourth-party (4PL) provider may be ideal in this case. These providers can customize entire logistics procedures, including negotiating contracts.

Which Organizations and Departments Use Logistics Management?

Some industries have a clear need for logistics management strategies. For example, product or technology (hardware/software) manufacturing, equipment manufacturing, construction, and the military have discernible and understood logistics mandates. However, the delivery of a newspaper, a program on television, a box of cereal at your local store, and a pint of blood for a surgical procedure are all made possible by logistics systems.

Other organizations also rely on logistics management:

- Freight companies, whether in-house or contracted, use and coordinate the services of airfields, ports, depots, and distribution centers.

- Telecommunications companies schedule and deliver phone access or information content through an intricate network of coordinated systems.

- Utility companies build miles of infrastructure delivery systems to bring water and power into homes.

- Governments prepare, process, and deliver services for daily operations, as well as for natural or man-made emergencies.

Publishing and editing houses, human resources/recruiting, wholesale distributors, financial institutes, and IT consulting firms also rely on logistics.

Within organizations, each business unit or department involved in the preparation of goods and services may have its own logistics plan in place. Logistics can be used to prepare and provide the products of marketing campaigns, curricula, and course delivery for universities, as well as to transport passengers by rail or air in all parts of the world.

Developing a Logistics Process Plan

A successful logistics management process is made up of Intricate and interwoven processes that are invisible to the end user. As with all initiatives, it starts with an analysis of what is required to succeed. These include the elements of financial planning, resource analysis, and change management. The planning process also provides opportunities to discover what is already in place and what needs to be added.

A plan can be formulated to specify in-house responsibilities, goals, and outsourcing opportunities. Plan considerations include inventory and warehouse storage capacities, transportation distances and territory, materials management strategies, personnel needs, vendor identification, technology upgrades, and information technology to manage the processes. Since logistics benefit from technologies that automate functions (as well as provide greater efficiency, visibility, and communication), it’s important to identify necessary technology upgrades while in the planning stage.

Once deployed, a continuous improvement process provides regular evaluations of the system to ensure upgrades, adjustments, and changes are made to optimize resources, reduce costs, and enhance operations.

The tasks for developing your logistics process may include the following:

- Define the goal and objective.

- Perform a needs analysis.

- Define methods of delivery.

- Select suppliers for various delivery methods.

- Define frequency of transport.

- Identify warehousing requirements.

- Choose supporting technology.

- Perform a feasibility study.

- Define each delivery process (land, sea, air, etc.).

- Implement process.

You can also create a dashboard to monitor inventory, orders, and process KPIs — this will aid in identifying opportunities for improvement.

Benefits and Challenges of Logistics Management

The ultimate goal of logistics management is a happy customer, but it must be balanced with the objective of developing cost-effective strategies that positively impact a company's bottom line and reputation. An organization can realize the benefits of logistics management by closely monitoring high-impact areas such as inventory and transportation.

On-time delivery is only part of the story. Along its journey to its destination, a product can be delayed by problems with the carrier, fluctuating fuel costs, and numerous other issues. To counter these roadblocks, logistic strategies can factor in load-capacity decisions, driver habits, fleet depreciation, alternate routes, and transportation options to alleviate cost pressures while maintaining a high level of customer service.

Back at the physical plant, balanced and traceable inventory can minimize warehousing problems while still maintaining material flow that keeps production lines working at capacity. Reverse logistics that also support environmental initiatives may positively impact the organization by clearing warehouse space.

The complexities of logistics management are best illustrated by the number of areas involved in the process. A problem at any point in the movement and flow of materials can set off a negative domino effect throughout the entire chain, resulting in profit loss, reputational damage, and productivity hits for the business. Below are some examples of what could go wrong:

- Damaged raw materials can cause production delays, work stoppages, and shortages of finished product.

- A broken-down truck, a work strike in a core support service, or a quarantined shipment also presents challenges.

- Lost or misplaced inventory slows down an entire production process, thus wasting both time and money.

- Capacity challenges due to undersold product, over-production, or market changes impact flow and movement throughout the chain.

- Uncontrollable challenges such as weather, strikes, or fuel costs can arise with little warning.

How to Become a Logistics Management Professional

Numerous colleges and universities offer bachelor’s and master’s degree programs in logistics management. Individuals with or seeking degrees in supply chain management, operations, and warehouse management are also strong candidates to take on the duties within an organization’s logistics department.

These programs stress business strategy, analytical and team-building skills, and general business coursework, including accounting, economics, international relations, and human resources as part of the curriculum. Many offer specializations in inventory, information, and transportation management.

The chart below provides more detail about obtaining a degree in logistics management:

How long does it take to get a degree in logistics management? | 4-6 years |

|---|---|

How long does it take to get a degree in logistics management? What are the prerequisites? | 4-6 years High school diploma |

How long does it take to get a degree in logistics management? How much does it cost? | 4-6 years $14,000-$62,000 per year, depending on the university |

How long does it take to get a degree in logistics management? What does the degree entail? | 4-6 years Business strategy, analytics, team building, accounting, economics, international relations, and human resources |

How long does it take to get a degree in logistics management? What jobs can you hold upon graduation? | 4-6 years Logistics manager, supply chain manager, transportation manager, distribution or inventory manager, airport manager, and warehouse operations |

How long does it take to get a degree in logistics management? What universities offer degrees in logistics management? | 4-6 years Auburn University, The Ohio State University, Purdue University |

According to the Bureau of Labor Statistics, a logistic manager's median salary is currently just under $75,000 per year and is projected to grow at a rate of 7 percent with increased opportunities in the global transportation sector. Other titles to look for in the industry include supply chain manager, transportation manager, distribution or inventory manager, airport manager, and warehouse operations.

Logistics professionals may also work in such areas as the following:

- Procurement logistics

- Distribution logistics

- After-sales logistics

- Disposal logistics

- International/global logistics

- Domestic logistics

- Point-of-sale (POS) logistics

- Emergency logistics

- Humanitarian logistics

- Digital/web logistics

- Demand logistics

- Plant maintenance

- Environmental health and safety

- Merchandising

- Plant maintenance

- Capital project logistics

- Asset control logistics

Resources for Logistics Management Professionals

There are a growing number of organizations that provide support, education, and industry insights to logistics professionals. These organizations offer information, news, trends, and professional development opportunities.

- Logisticsmgmt.com issues a free newsletter and magazine that covers the state of the industry.

- Supply Chain 24/7 delivers news, case studies, research, and webcasts for transportation, distribution, logistics, and supply chain professionals.

Many membership organizations focus on specific areas of logistics, including the American Production and Inventory Control Society (APICS), the International Warehouse Logistics Association (IWLA), and Logistics & Transportation Association of North America (LTNA). Other organizations support the work of an entire supply chain, such as the Council of Supply Chain Management Professionals (CSCMP), and industry-specific associations, such as those that speak on the unique issues of healthcare or education.

Tips for Implementing an Effective Logistics Management Program

The logistics management industry defines the "7 Rs" of an effective program as follows:

- Providing the right product

- In the right quantity

- In the right condition

- To the right place

- At the right time

- To the right customer

Some cite another "R" when addressing the trend for sustainability and identifying products: made the "right way."

This deceptively simple definition is not easy to achieve. As stated, many elements need to work in a coordinated and logical process to achieve the desired result of a happy customer. Many experts advise simplifying rather than overcomplicating when coordinating the “7 Rs.”

Logistics management benefits from effective planning, the right support software and automation tools, and effective management of the high-impact areas such as material, transportation, and inventory. Finally, cultivating a culture of continuous improvement requires analyzing, measuring, training, and adjusting to trends and opportunities. The end results include enhanced customer satisfaction and loyalty, greater productivity, and increased profits.

- Identify your goals and major stakeholders.

- Design your logistics management process in order to measure against your goals. Employing a logistics management consultant may be necessary at this stage.

- Implement nomenclature standards and controls in order to ensure accurate data collection.

- Find the right software solution that also matches your industry standards.

- Extensively test the software solution against your process before it is implemented.

- Monitor, analyze, and adjust to improve the logistics management program.

Download Logistics Management Scorecard

Although the famous UPS logistics commercial avows this practice “makes the world work better,” for many organizations it is really about making their supply chain work more efficiently. There is increasing pressure on every organization to provide goods and services to more regions and at top speed. The elements of timeliness to satisfy impatient customers, cost containment to stay competitive, and global influences and challenges contribute to the growing importance of logistics plans and processes. Businesses must incorporate strong practices in order to meet consumer expectations, and the one with the best logistics will be poised to win in the marketplace. The growth in degree programs, support organizations, and training speak to the need for qualified logistics management practitioners in today’s global and growing market.

Take Control of Logistics Management with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.