What Is Process Improvement?

Sometimes referred to as business process improvement (BPI), process improvement means breaking down all the activities and procedures in your company and identifying where you can implement efficiencies and enhancements. Process improvement should be performed during regular organizational development, and when businesses are restructured.

Practitioners identify, analyze, and improve upon existing business processes to meet new standards or goals by modifying or eliminating a process, or complementing with sub-processes. After making decisions about what to change, conduct an analysis on any tangible improvements.

Process improvement is more complex and challenging than most managers realize and requires using a systematic approach with one of the available methodologies. Without this structured approach, momentum for change is near impossible to maintain. Further, bad habits and poor workflows become normalized in a busy working environment. One example of a structured methodology is benchmarking, which is a continuous improvement methodology that compares performance metrics and best practices across companies and industries. This ten to twelve step approach capitalizes on what companies are doing in a similar industry that can help shepherd improvement into another industry’s companies.

Practitioners of process improvement should always incorporate change management principles, so they can have a systematic way of dealing with any process changes. Change management seeks to ensure that any changes made to processes are implemented correctly and its benefits are realized over time. According to an article in the Wall Street Journal, about 60 percent of improvement initiatives fail over time due to team resistance and poor communication. Change management principles ensure that your initiatives succeed by removing these roadblocks and implementing a plan to avoid the typical mistakes.

One helpful concept in process improvement is process mapping, which is the creation of workflow diagrams that show all steps in a process and any parallel processes. Before changes are made, practitioners can visually show where processes are and what steps they involve, which can possibly reveal bottlenecks.

In healthcare, process improvement focuses on moving towards a value-based model for treating patients. Process improvement and its methodologies are a key component in the future of healthcare. Healthcare administrators will use data, standardization, and the reduction of process variation, and will benefit from using the same methodologies as business, such as Lean and Six Sigma.

There is much debate about process improvement as a discipline and whether one specific methodology is best. Process improvement is a generic term that refers to the simple principles of identifying opportunities, making changes, and measuring the changes’ affects. Some practitioners add a methodology to their terminology, such as continuous improvement (Kaizen), which is a Lean process improvement methodology.

Below are the key concepts of this this type of process improvement:

-

It is a mindset, not a one-and-done activity. As a mindset, activities become a part of the regular workflow. Make it a practice, not a one-time event.

-

For best results, practice across your whole agency. Every part of your business should be willing to regularly review their workflow for improvements. Without the entire business on board, there is a risk that optimizations in one department actually cause another department to become less effective. For example, if your IT improves a software program but your HR does not improve the training to include this software, users can become frustrated and at the worst, lose time and work.

-

Your business will deliver more value faster. Using a systematic, scientific approach to process improvement, you will notice your business can deliver better outcomes in a shorter period. The proof is in the metrics.

Every type and facet of business can benefit from process improvement. Some specific examples include the following:

-

Information Technology (IT): IT is part of all sides of process improvement. Most IT departments serve not only external customers, in the case of technology firms, but also their internal customers and departments, as well. Strong IT can become a tool for process improvement throughout a business, as they can combine with other parts of the company to provide a value stream and implement their own process improvements to better serve their external and internal clients. For example, in a data center, the amount of power a company has determines how many services they can supply. Purchasing or developing the ability to measure power usage at the user level is their first step. IT would review the measurements of each user monthly to determine identify overages and possible violations. They would use this information to determine if certain activities (such as streaming music and mining for cryptocurrency) require more power and then put policies in place that disallow them.

-

Government: Although notoriously challenging due to their need for a low risk environment, improving processes in government is possible, and some would say even critical. Some examples of process improvements in government include looking at permitting processes for the inefficiencies, gaps, and possible ways to expedite. Another process improvement opportunity for government services is to collocate them, where possible, to better serve customers who need several services. For example, instead of visiting several agencies to get their birth certificate, passport, and traveling warnings, they could go to one location using the same system.

-

Warehouse: Warehouses are hotbeds for inefficiencies. Customer demand for variety constantly increases the number of assorted products needing to be stored, tracked, and shipped. Improvement projects can focus on slot analysis, optimization of product storage, improvement of pick path flows, labeling of products, housekeeping, lighting, and the constantly needed reconfiguration of the storage system.

-

Software: Especially in service-delivery software firms, failure demand, also known as requests to correct mistakes, is a huge source of waste. For process improvement, these firms should focus on why customers are calling and if there are consistent reasons for the failure demand. This process would take place instead of the typical metric of reducing cost per call answered in order to increase customer satisfaction and free up new service capacity.

What Are Process Improvement Goals and Objectives?

Businesses are in business to thrive and make money. Whether a company is trying to remove waste and friction or improve customers satisfaction, performing basic process improvement initiatives in a measured, structured way can make a difference. Other goals or objectives for process improvement projects can include the following:

-

Decrease process time.

-

Improve the quality of products and services.

-

Be in better compliance with regulations or laws.

-

Meet customer demands and goals.

-

For drastic transitions.

-

To address the root cause of deficiencies.

What Are the Steps in a Process Improvement Project?

When process improvement is successful, the business’ goals and needs, as supported by processes, are optimized. Practitioners start with the business needs and then figure out which processes support them. Next, they analyze the processes for any necessary improvements, gaps, and bottlenecks. Leaders can then focus on redesigning and reorganizing the processes where necessary, and possibly designating different staff or departments to own them. Innovative technology to support these processes may be considered or determined.

Miles recommends taking the following five generic steps:

1. Define the processes that make up the organization and the most important key indicators of each phase of the process. It is necessary to know the indicators and measure them to know where the improvements should be carried out. For example, if you are digitizing the administrative part of the company, the key indicators would be the reduction of time in manual tasks and cost savings, among others.

2. Determine the phase(s) of the process in which it will seek to improve the indicator that was initially chosen. It is better to modify the phases one by one, as this will show the accuracy of the results achieved. If too many things are changed simultaneously, you will not be able to tell whether or not the change was positive.

3. Once you plan the phase(s) that must be improved, design the process. Be clear about what objectives you want to achieve. Once the design has been established, choose the technological resources to carry out the processes, measure their results, etc. Next, define the timings of the process and respect it when you start. Finally, involve the team from the beginning of the improvement process.

4. Mark the appropriate objectives you want to reach and identify opportunities for improvement and what resources are needed to achieve those objectives.

5. Using metrics, constantly monitor and follow the process. The objectives that were given in an improvement process may change over time. Consistently review the processes and see if they change, in addition to noting if they have achieved the improvements they wanted.

4 Steps for Continuous Process Improvement

As the world changes and technologies evolve, so does process improvement. More formally, and regardless of discipline, practitioners can follow four steps for regular or continuous process improvement:

- Recognize the Need for Change: Whether you conduct regular process audits or have a great idea, notice areas in your company that have issues. Perhaps there are many issues. Prioritize these needs by reviewing how each problem and its associated processes affects your business and customers. At this stage, ask the following questions:

-

What is the purpose of each process?

-

Who is the customer that each process effects?

-

Where are the pain points?

-

What process limitations are getting in the way of achieving our strategic goals?

-

What systems do we need to put in place to make continuous improvement a permanent part of our culture?

-

How do we measure the improvement, given the results may be hard to quantify?

“It is easy to overtrain employees and inundate them with tools and techniques they may rarely use. Senior management needs to be trained to identify the systems in a company and focus on getting them aligned with company strategy. Once specific issues are identified, simple problem solving and measurement techniques are best. If there are specific operational issues where results are easily quantified and manipulated, more sophisticated techniques, such as experiments, can be used.”

- Review Your Current Processes Closely: Once you have figured out what processes need to be revamped, you will need to review the procedures they are part of, so you understand from beginning to end what is related. There are many tools you may use for analysis, including process mapping, cause and effect analysis, and operational surveys. Regardless what you use, you should also be asking the following questions:

- Which steps in the process have bottlenecks?

- Are there any break points in the process?

- Where are the most delays?

- Where do the costs escalate?

- Where does quality suffer?

-

Get Executive Sponsorship and Staff Buy-In: Before you can really decide on changes, you need to ensure your senior management and staff are on board. Present your case for change and what effects the issues have on the business to senior management. You need to help the staff understand that change is meant to improve their work as well to get buy-in.

- Develop Your Improvement Strategy: Now that you have completed your process analysis phase, it is time to develop a strategy to fix problems. It’s time to figure out how some of the processes may be fixed and set goals that align with your business’ strategic plan.

How to Identify Process Improvement Opportunities

In the global business climate, companies are always looking for ways to usurp their market rivals. To help your company be competitive, process improvements are a critical component of your overall strategic plan of growth and expansion. Whether you have a staff improvement specialist, or have a culture of improvement throughout, someone should be familiar with all your business processes. A firm grounding in how your business works overall should not just be left to employees, however. Higher-level management should have enough engagement that they can identify opportunities. Outside improvement consultants should interview as many employees as possible, especially those in key positions.

All company process should be charted out visually. Whether you choose casual workflows or more formal BPMN diagrams, identify the core business processes first. Gather and earmark data that describes inputs and outputs of the processes with each visual. These could include things like inventory, costs, monthly sales, customer demand, production lead time, labor hours required, and space requirements.

Ask the experts (also known as your employees) where they think waste occurs. They can help you determine processes or portions of processes that do not add value. Conduct a root cause analysis to identify opportunities for process improvements.

There are many opinions on how to prioritize your improvement processes and possible projects. One way is to rank opportunities based on the following:

-

Legal requirements, national guidelines, or industry necessities

-

Projects aligned with your strategic plans, mission, or institutional objectives

-

Improvements that are important to staff or stakeholders

-

Improvements that address issues or processes that elevate risks, cause problems, or occur in high volume

-

Realistic improvement projects for your team

Process Improvement Failures

Even with the best of intentions and resources, businesses get embroiled in process improvement projects that fail. If you have already developed a culture of improvement, and have buy-in and the right tools, you can be successful—in theory. In a qualitative study, researchers identified the below top ten reasons for initiative failure:

-

Lack of managerial support

-

Inadequate communication

-

Teams with insufficient skill sets

-

Inadequate training

-

Poor choice for process improvement methodology

-

Lack of incentive for success

-

Scope creep

-

Teams too small or not diverse enough

-

Lack of follow-up

-

Not using change management methods

These may be self-evident, but there are still some questions to consider:

-

Are you performing point optimization? Point optimization occurs when one business unit or program is excelling. These units are optimized as much as possible, but they are surrounded by or connected to other business units or programs who are suboptimal. Your system is only as strong as its weakest subsystem.

-

Are you focusing too much on the cost? Saving money is the point, but to save money you need to work smarter and not harder. Consider splitting work into different functional areas, outsourcing low skill work, focusing your staff on fewer types of tasks, using incentives, and scheduling staff more closely to increase efficiency.

-

Are you over-relying on technology? Do not let your technology lull you into false security. Add some low tech to your day by having regular staff check-ins, whether a ten-minute daily standup or a weekly meeting.

-

Are you adding more process to your process? The only authentic way to improve a process is to add checks, balances, constraints, or policies to your existing processes. The goal is not to add complexity or additional steps, but clarity.

-

Are your processes the master of common sense? It is important to give your staff clear instructions, but they should also be given the leeway to improve things based on what is happening around them. They need enough guidance to understand the vision and intent of the processes, but also enough authority to override processes when they do not make sense.

-

Are you taking human nature into account? At the end of the day, your staff are still people. It is all well and good to design something that makes sense for the business needs, but if you are not appealing to the people performing the work in some way, there could be a fatal flaw in the workflow. Remember to include people in the design and consider human nature when testing a new process.

-

Are you getting buried in the jargon? Hiring people who have the right credentials and experience for their position is important, but you need to be clear about business needs. For example, you could be looking for a Lean Six Sigma Black Belt on paper, but in actuality need someone with soft skills to assist with change management. Don’t forget that methodologies can be learned, but that it is much harder to teach skills like leadership and compassion.

What Is a Process Improvement Methodology?

Every consulting firm and process improvement practitioner will tell you that their preferred methodology is the best. This can leave an organization at a loss when considering the substantial number of competing disciplines all meant to achieve a similar goal. In this section, you will find an overview of the most popular and well-researched methodologies, including Kaizen, Total Quality Management, Six Sigma, Lean, and more.

Kaizen

A Japanese word for improvement, Kaizen refers to all the activities that constitute a continuous improvement and involves everyone in the company from the top down. This strategy, born in the Toyota company after World War II, is part plan and part philosophy. In a manufacturing facility, the action engages everyone in specific improvement events, especially those on the manufacturing floor, and the philosophy pushes the culture to constantly ask for suggestions and improvements until it is a natural way of thinking. Kaizen works together with standardized work, known as the best current practices.

To run your own Kaizen event, use this template to keep track of your work.

Download Lean Rapid Improvement (Kaizen) Event Results Template

Word | PDF | Smartsheet

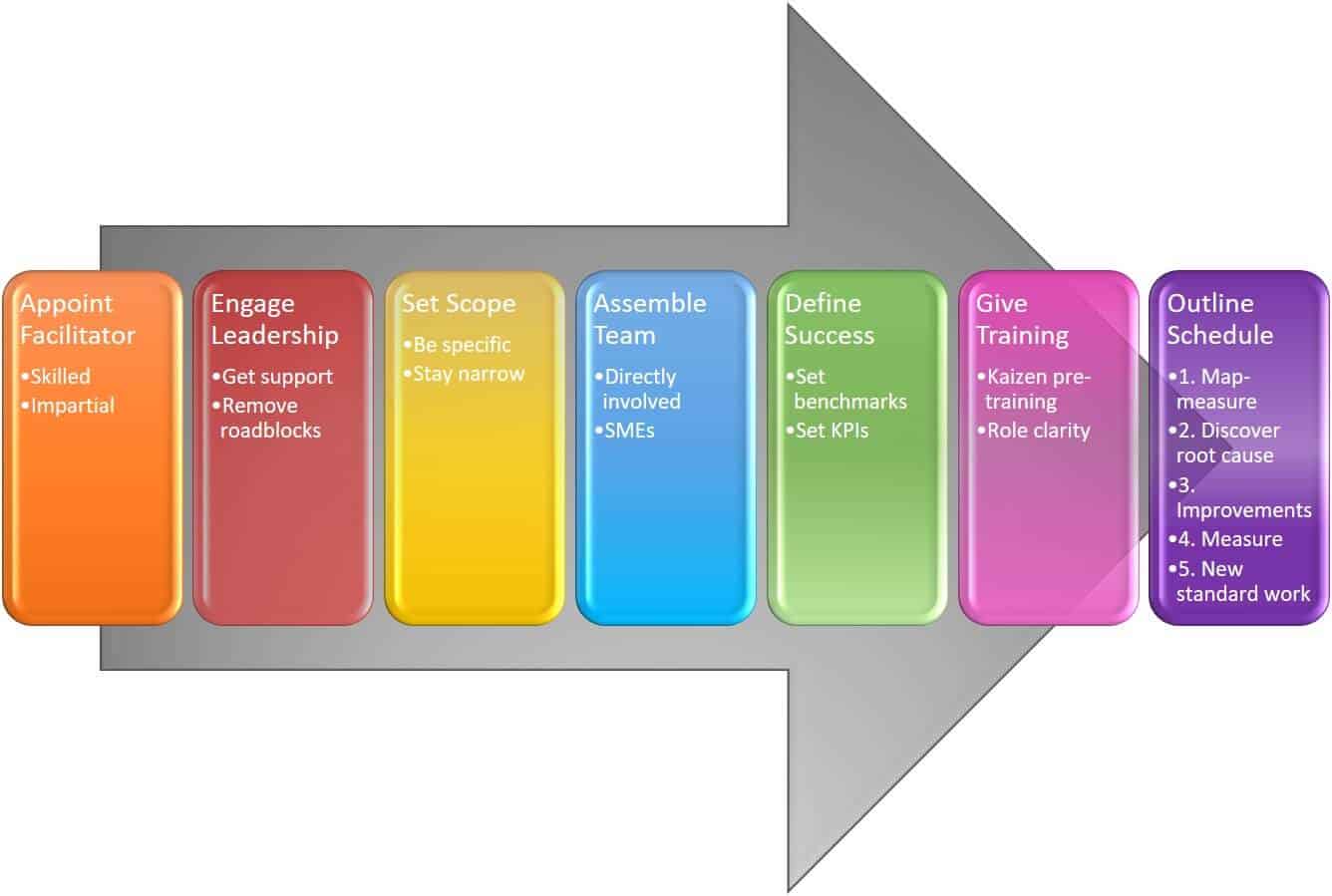

Kaizen events usually last about a week, and have a facilitator focusing on a specific problem. This graphic depicts the seven steps to getting a Kaizen event off the ground:

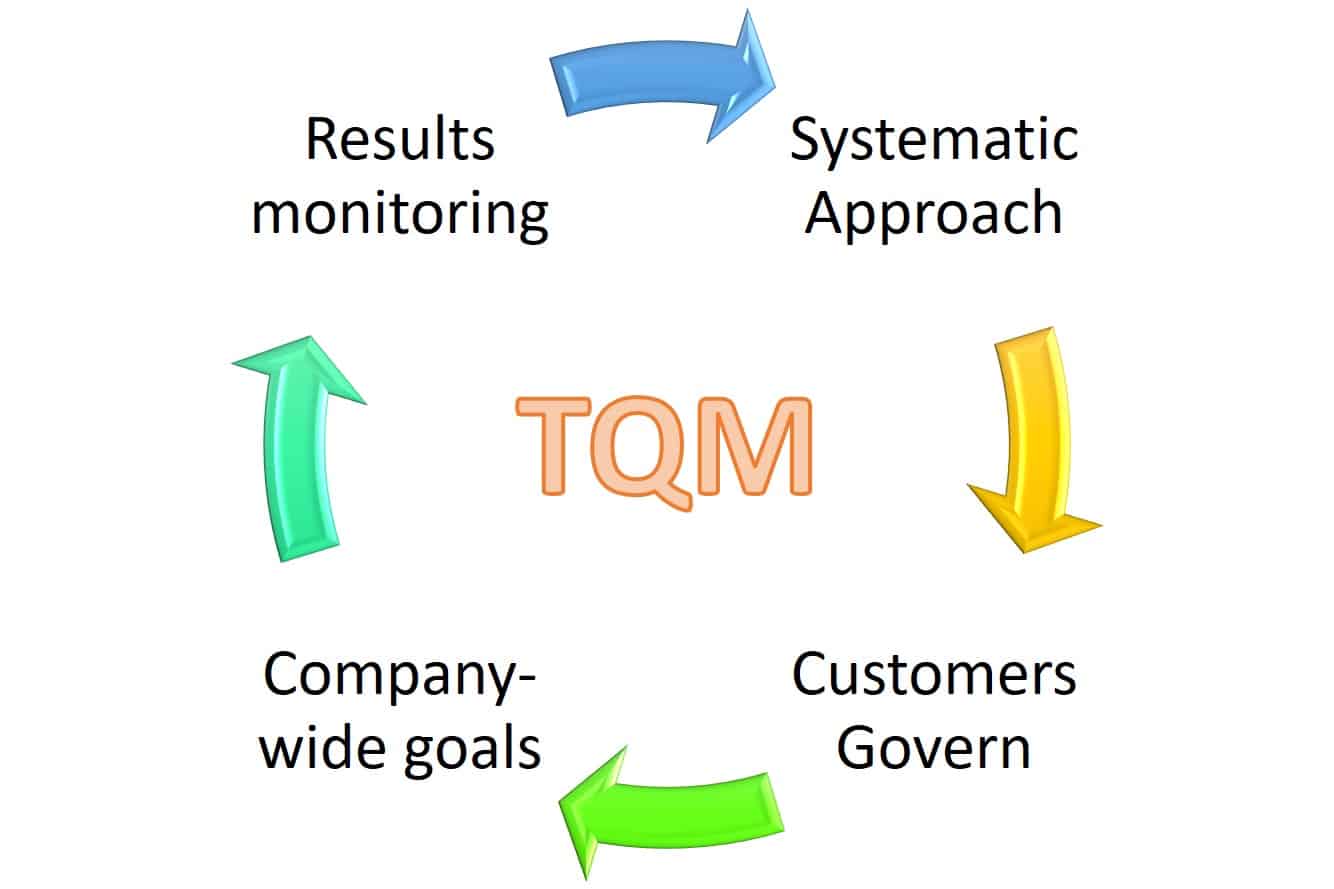

Total Quality Management

With theory that predates both Lean and Six Sigma, Total Quality Management (TQM) practitioners have four tenets:

-

Use a systematic approach.

-

Customers govern the quality level.

-

Everyone works toward the same goal.

-

Monitor for results.

Developed by William Deming, TQM comprehensively reviews the internal guidelines and process standards to decrease errors. The methodology is mainly used in manufacturing, but is also applied in the military, manufacturing, medicine, and finance, as it targets line production, its corresponding practices, and industry standards. Decisions are made based on facts and performance metrics, and organizational communication is encouraged to maintain employee buy-in. For more on TQM, see “A Quality Principle: Everything You Need to Know about Total Quality Management.”

Six Sigma

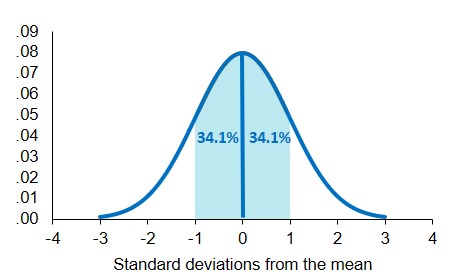

The goal of Six Sigma is to eliminate defects and thereby improve the bottom line. The methodology borrows from TQM heavily, but shows a true improvement over TQM. According to researchers, Six Sigma targets TQM’s weaknesses and improves upon them. Six Sigma takes from the mathematical concept of standard deviation (referred to as the Sigma), which is a statistic that tells you how closely all the data points are to the mean (the central tendency) for a given process. When all the data is tightly clustered around the mean, the variation is small; When the data is spread apart, the variation is large — standard deviation is measured by this distance. On a bell-shaped curve, one standard deviation from the mean in either direction accounts for 68.2 percent of all the data in a group. Two standard deviations account for 95 percent of the data. Three standard deviations account for 99 percent of the data, and so forth.

The goal is Six Sigma, which means that all the data is as close to being tightly aligned with the mean as possible, so that defects are less than four in one million measured. In the manufacturing world, this means that less than four in one million products manufactured have defects. This mathematical model evolved to not only decrease manufacturing defects, but also to decrease defects company-wide. To learn more about Six Sigma, review “Six Sigma for Beginners.”

Lean

At first blush, Lean seems like a collection of different techniques and tools. The two main tenets of Lean are continuous improvement and valuing people. Starting as a manufacturing process, Lean quickly became a business methodology. In Lean, practitioners try to find waste and remove it. Techniques include team exercises, error proofing, and cross-training. Waste comes in all shapes and sizes. The seven main examples of waste are show below:

-

Moving goods or services farther than necessary

-

Delays between stages

-

Unnecessary movement of employees (i.e., travel)

-

Overproduction

-

Overprocessing

-

Errors

-

Misusing or under-utilizing the skill sets of employees

Ward has experience with Lean in a variety of fields, but one story stands out. “One of my favorite stories was with one of the branches of the military. Before we came in, the troops were pushing a torpedo the equivalent of a marathon during rebuilds. We got everything set up in the waste-free manner and reduced that number to several hundred yards.”

If you’re just getting started using Lean to help eliminate waste, Ward advises, “I would advise new practitioners to just keep doing good work and the results will speak for themselves. Once you have a core group of practitioners the momentum will build. Make sure you keep the business leader in your corner and that they are your biggest evangelist. be patient and do the right thing.”

For more on Lean, see “The Definitive Guide to Lean Project Management.”

Rapid Improvement

Not necessarily a discipline on its own, rapid improvement can include Kaizen and the Just-Do-It frameworks. The point of rapid improvement is to quickly put solutions into place once you identify the problem and the solution. Not every problem in a company will require the rigor of Six Sigma, and using that methodology in every instance can give your process improvement initiatives a negative cast.

Agile

Mainly used in software development, Agile is the project management technique that helps with unpredictable environments. Agile uses incremental, iterative steps arranged in sprints, or development cycles. Teams build in rapid feedback, continuous development, and quality assurance into these iterations. Decisions must be made quickly in an Agile environment, but proponents of Agile say that resources are used more efficiently, problems are identified and fixed quicker, and there is increased collaboration among users.

For more information on Agile, see “Everything You Need to Know About Agile Project Management.”

How to Choose the Right Methodology for Your Company

The simplest way to decide approach to use is to either leverage your senior leadership’s experience or hire a consultant. Many consultants use routine strategies that are meant to implement, train, and provide short-term support.

You can also use the following problem-solving approach:

-

Identify the problem.

-

Analyze the problem for a root cause.

-

Develop alternate solutions.

-

Select the approach that makes the most sense. Here is where you would hire outside help if you do not have the inside expertise.

If your organization is more mature, you’ve likely already completed some improvement exercises. As a part of your assessment and strategy, use this historical information to determine what worked and did not.

When selecting a process improvement approach, consider the different methodologies. Sometimes, methodologies are used interchangeably. For example, Kaizen and Six Sigma are both continuous improvement methodologies that focus on improving efficiency. Six Sigma focuses on output, or the final product, rather than the culture. Lean concentrates on eliminating waste, and the rapid improvement methodologies start with the end in mind. Lean and Six Sigma have been combined into a methodology that has had success for many companies that some researchers consider to be the gold standard.

According to some experts, if the problem is complex, has been difficult to solve in the past, or causes a lot of variance in your products, you should use Six Sigma to solve it. If you want to get more done quickly, or want to eliminate non-value-add activities, turn to Lean. You can also combine Lean and Six Sigma. If you need to approach the issue quickly and get quick results, consider a Kaizen event. If you know the answer to a problem and can make the change within 24 hours (and return to the original state in 24 hours if it does not work), then apply rapid improvement. These are a few of the many methodologies available presented at a high level.

Sometimes a methodology speaks to a practitioner and as such, choosing one is more a matter of what someone has learned, rather than a methodical review. At a minimum, all process improvement methodologies share the philosophy that businesses and their process can be improved. Earlier methodologies subscribe to the idea that statistics and measurements are essential. Finally, they all share the idea that the people closest to the work have the best insight into how to improve it.

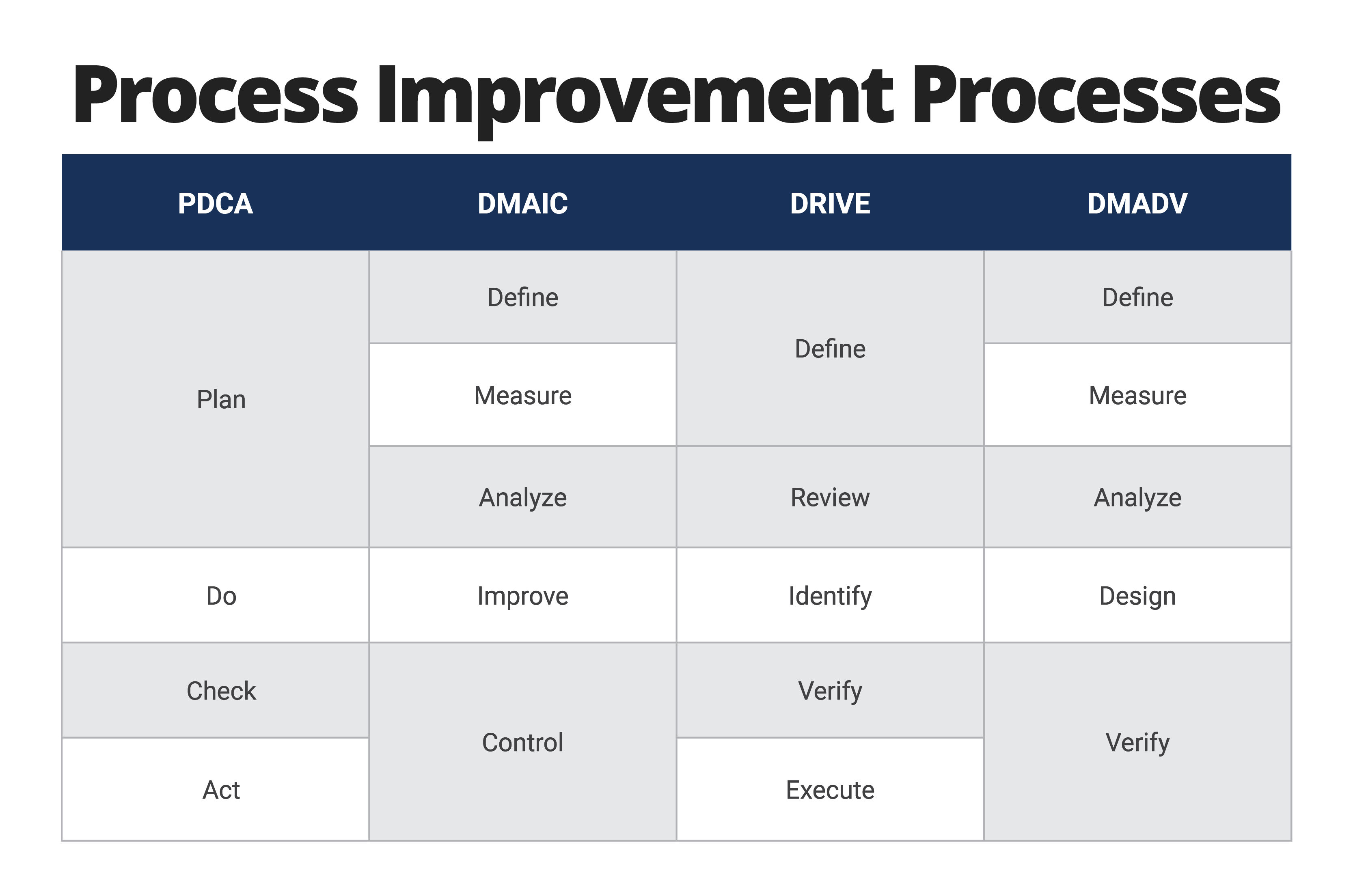

The Process Improvement Processes

There are several different cycles you can tap into to lend structure to your process improvement projects. The difference between these “cycles” is in the definition of the steps. The following chart shows the differences:

Plan-Do-Check-Act (PDCA) Cycle

The goal of TQM, Lean, and any continuous process improvement methodology is to speed up and increase the value passed to customers. This is a continuous cycle of four steps: plan, do, check, act. Regardless of the actual term used in each step, it involves the following:

-

Plan: Implementation and assessment of a new or current process must be planned. Practitioners should carefully plan the metrics, initially erring on the side of smaller changes and measurement.

-

Do: Perform the plan developed in the previous step and measure.

-

Check: Gather the results and measurements from the previous step and assess them. Compare this data to what is expected, and review the process during this step. The best way to see differences in the process and outcomes is to chart them and look for trends.

-

Act/Adjust: Now is the time to enhance or adjust the process. Using data from the prior two steps, you can determine the root causes of any issues. At this point, you should also evaluate risk. If your actions or adjustments were effective, you will not see the same issues during your next cycle.

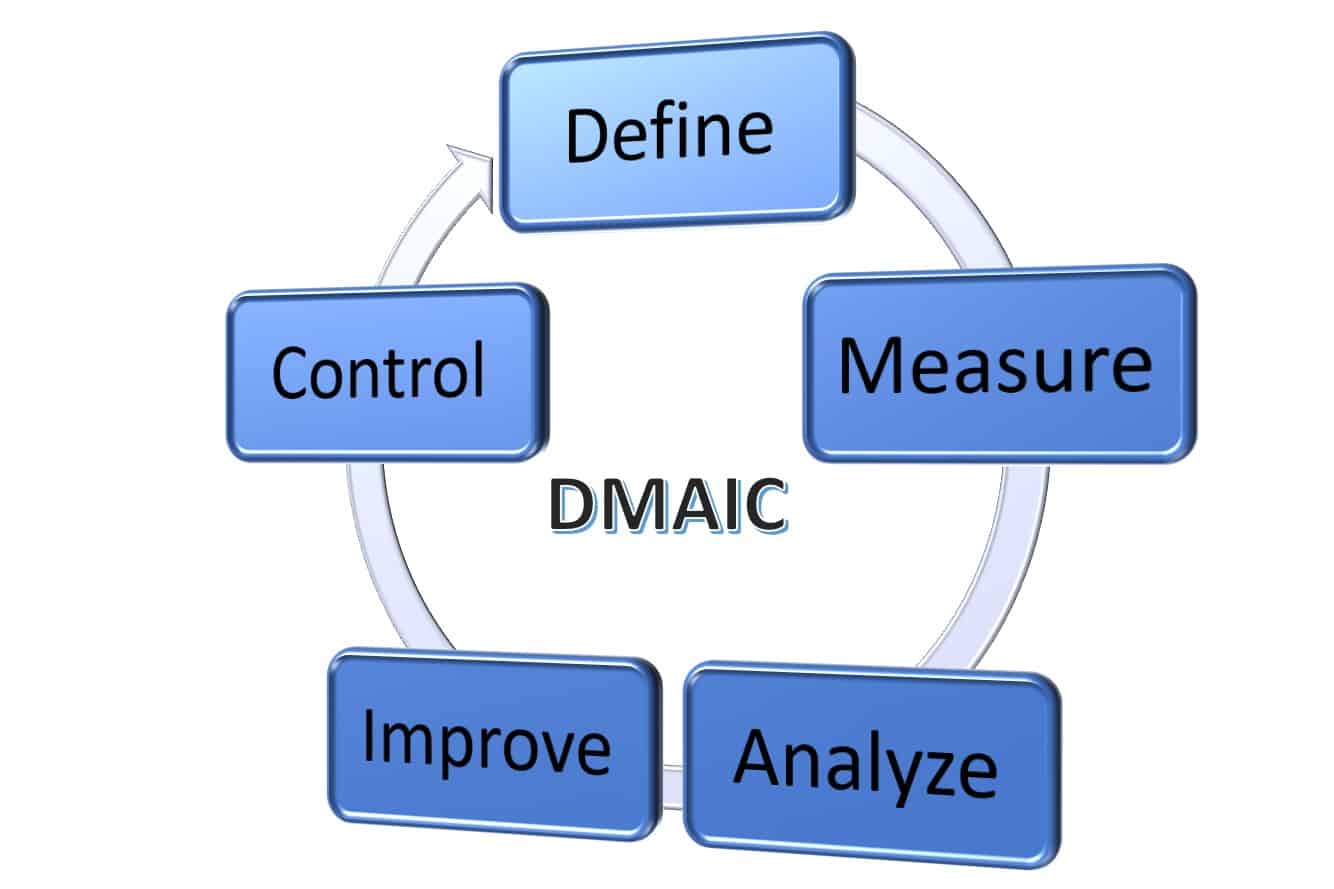

Define, Measure, Analyze, Improve, and Control (DMAIC)

Associated with Six Sigma, DMAIC stands for define, measure, analyze, improve, and control. This scalable process is similar to the PDCA cycle in that it is an improvement cycle that focuses on existing processes.

Below are the DMAIC components:

-

Define: Formulate the business problem, including all goals, resources, timeline, and scope. Identify your customer, what they need, and how the problem affects them.

-

Measure: Before you know how much you want to improve, you need to know your baseline. The team must decide what to measure and what realistic improvements you can make to this baseline over the potential root causes of the problem and in what proportion they cause the problem.

-

Improve: Once you have fleshed out the problem’s root causes, you need to identify, test, and try the solutions, whether in part or whole.

-

Control: To ensure the changes stick, they must be embedded in the process. Perform any approvals or workflow changes to ensure they will become part of the new process.

Whether you choose the PDCA or the DMAIC cycle is up to you and the needs of your project. PDCA is the basic, cyclic methodology that predates others and relies on a qualitative approach. DMAIC relies more heavily on data and is better for projects that pose more risk or expense. Use a quantitative approach and statistics to problem solve using DMAIC and think of it as a flowchart with an endpoint.

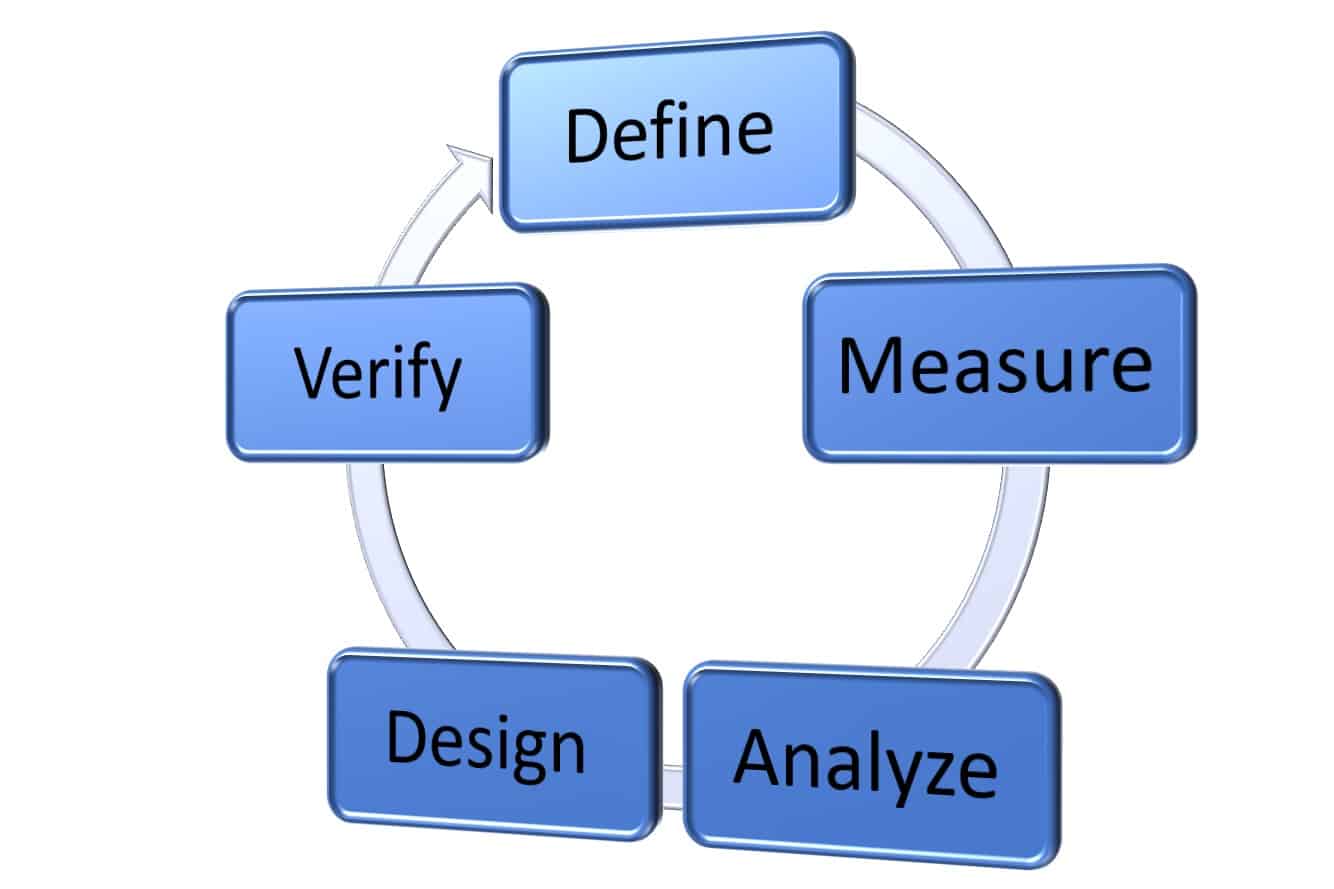

Define, Measure, Analyze, Design, Verify (DMADV)

The DMADV cycle is the same as the DMAIC cycle in Six Sigma, except it is used for new processes. Since you are developing a process, the last two steps are necessarily different.

The basic steps in DMADV are as follows:

-

Define: Keeping in mind your company’s overall strategic plan, define the goal of the process.

-

Measure: The critical to quantify factors are captured in this step. These factors are your customers’ critical needs, divided into the factors that customers use to evaluate their quality. Those factors are divided again by the performance requirements you need to provide a high-quality product.

-

Analyze: Review potential design options.

-

Design: This is the process development step.

-

Verify: The new process is piloted, ensuring that the design meets both the process and the customer goals.

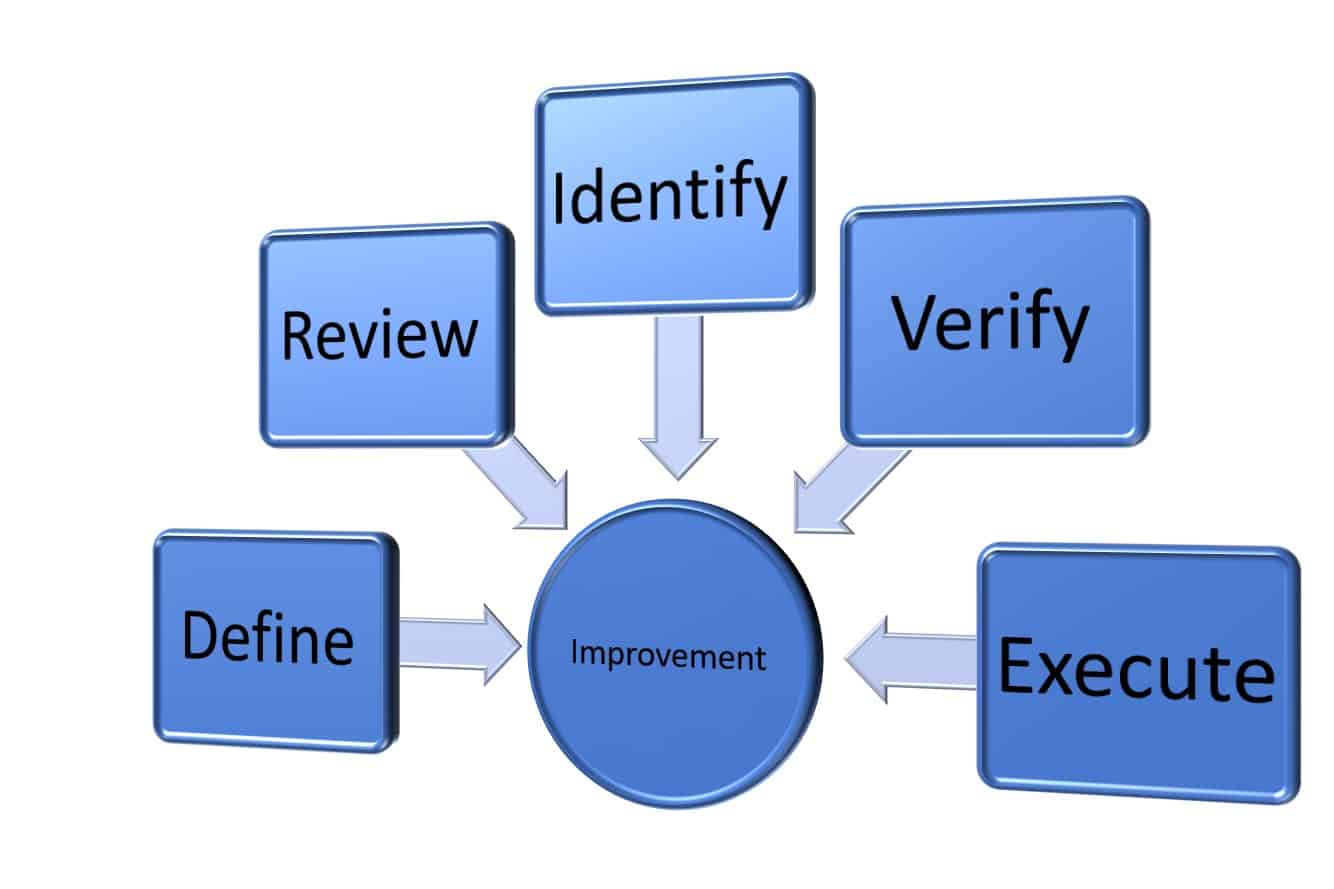

Define, Review, Identify, Verify, Execute (DRIVE)

DRIVE is another approach to the PDCA and DMAIC cycles, except it is not a cycle of a flowchart with an end. DRIVE is formatted as separate things to consider during process improvement, which can help you to analyze a problem using different approaches. If possible, put different people in charge of each step.

DRIVE includes the following aspects:

-

Define: Determine the scope of the problem, alongside what success would look like in fixing the problem.

-

Review: During the review step, decide on metrics after you gain a full understanding of the background and situation, via a review.

-

Identify: Acknowledge necessary changes and viable solutions.

-

Verify: Check the proposed improvements to see if they will bring about the expected changes.

-

Execute: Implement the changes, gather feedback, and perform a review.

How to Pick the Right Process Improvement Tool for Your Situation

To pick the right tools for your project, first become acquainted with what is available and what the tool does. Next, get to know your project. Irrespective of the process improvement methodology you choose, you can always dip in and out of other methodologies and use the tools and techniques that suit your situation. The following are different tools and techniques, why one would use them, and what methodology they derive from.

Process Mapping

Process mapping, also called brown paper process mapping and analysis, refers to creating detailed visual displays of all the steps from beginning to end. These visuals help to manage workflows. Examples of process maps include flowcharts, swim lane diagrams built in BPMN, state diagrams, data flow diagrams, and value stream mapping. Assembling process maps enables organizations to understand and picture the steps, inputs, outputs, resources, team members, strengths, and weaknesses in each process. For more information see “Essential Guide to Business Process Mapping.”

Statistical Process Control (SPC)

Statistical process control (SPC) is the tool of TQM that mathematically reduces the variation. SPC uses statistics to scrutinize and control a process. Using industry standards, quality data is compiled in real time during manufacturing and graphed with control limits set by the process capabilities. When data falls in the control limits, it means the operations are working as expected.

Simulation

Acting as a powerful tool for process improvement, simulation is an efficient way to scrutinize your operations under a variety of conditions. Most simulation is done with a software program targeted to the specific process. You can insert randomness and experimentation into a simulation to help your business figure out what they would do and possible breakpoints.

Kanban

One of the tools of continuous process improvement methodologies is a visual workflow tool called Kanban. You can also use this tool for projects that require rapid improvement on specific projects and teams. Write each step (in the case of one project) or project on sticky notes, notecards, or tickets, and arrange the visual cards in columns that display the stage of each task or project (examples include ready, doing, and done, and to do, in progress, and completed). Other concepts for Kanban boards include work in progress (WIP) limits, which limit the maximum number of work steps or projects in each column — this helps keep your teams narrowly focused. Others include a backlog for ideas and projects (often called the parking lot), and the delivery point that details the amount of time each task takes to move from the first stage to the last. This is where the continuous improvement comes in: the time from the first to last column should decrease. Read more on Kanban here.

Operations Analysis

Sometimes called operational research or industrial engineering, operations analysis is the study of an operational system to improve it. There are six steps to operational analysis:

- Outline the problem. The best problem statements get to the root of the issue without posing solutions or explaining what the problem is not. The problem statement format should contain the object and the defect.

- Determine what data you have and what data you need. Strong data collection is not for the faint of heart. Be extremely specific about what questions you are trying to answer. For example, if you are trying to figure out whether your product modification works for your customers, ask them specific questions about the modification, not whether they enjoy the product. Benchmarking looks at the best practices in your industry and in other industries and then determines how your data lines up.

- Determine the patterns. Some data collected is more important that other data. If you follow the Pareto principle, which states that 80 percent of your effects or problems are caused by 20 percent of your issues — or better yet, that 80 percent of your results come from 20 percent of your actions — then you understand that fixing some pain points has a larger effect than others. Experts suggest that a visual analysis of your processing will provide a distinct perspective than will words on paper or telling the story. Be aware that random variations can occur and may not constitute a trend. Finally, look for the bottlenecks that surely exist. You can find bottlenecks just after the backlog, where you find unhappy customers.

- Steer clear of making rash conclusions. Before you point fingers at anyone or decide anything, make sure that the data supports it. Consider the effects before placing any blame.

- Come up with solutions. Initial brainstorming sessions should be facilitated by someone who can ensure the group is not trying to gain an advantage over each other by shouting out disparate ideas. Instead, focus the group on one idea and add or expand that idea into many concepts. Use the mutually exclusive, collectively exhaustive principle (MECE) when divvying up your ideas: Categories should be mutually exclusive to avoid being counted more than once and drill down to create a list of all the viable solutions. Have a category labeled “other” so you don’t miss anything.

- Test. Once you determine with process tweaks, test them. Tweak from what you’ve learned and test again, until you have the process the way you need it.

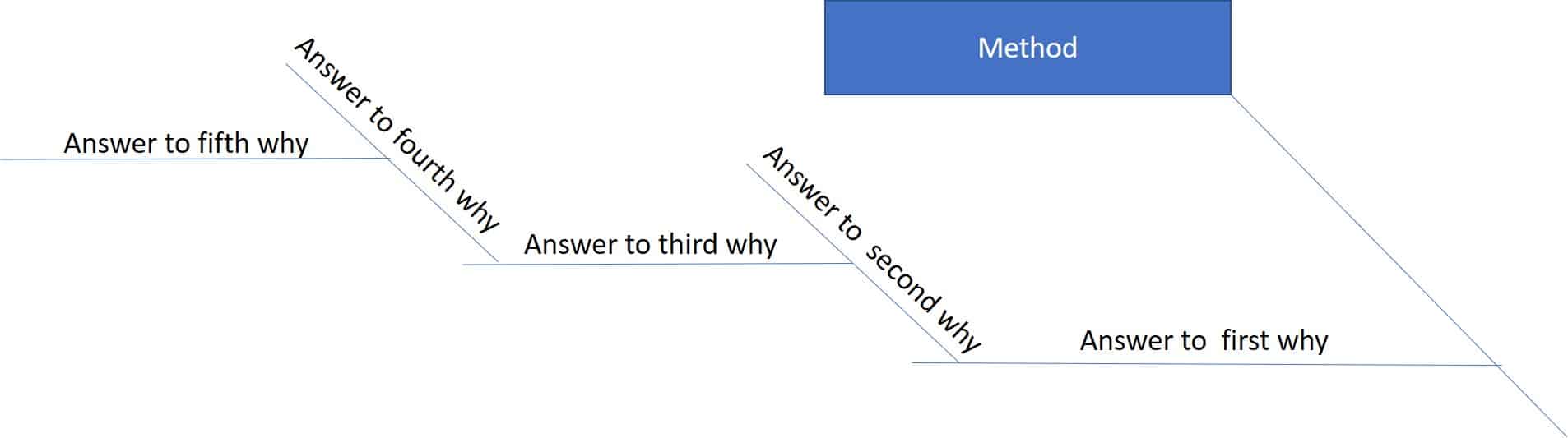

The Five Whys

This simple concept ensures that in any issue, you look behind the face value and ask “Why?” five times until you get to the root of a problem. Each answer to a why question forms the basis for the next question, and is meant to be used when troubleshooting, problem solving, or in quality improvement projects. The five whys is most effective with simple or moderately difficult problems. This tool urges you to follow a specific track when there could be several tracks that you need to follow.

Download Five Whys Template

Excel | Word | PDF | Smartsheet

Here is one example of how a five whys process might look:

1. Why did the software fail?

The database overloaded, causing it to seize.

2. Why is the database overloaded?

There is insufficient space, so it seized.

3. Why is there insufficient space?

We have another piece of software that used the space.

4. Why do we have another piece of software using the space?

We planned to have them share.

5. Why are they sharing?

Because we do not have a dedicated database for the new software yet.

This is a simplistic example, but what you do not see in the questions is embedded solutions. You see a portion of the answer drilling down into the next question. This method is popular, particularly with Lean practitioners, when trying to find out why something unexpected has happened. The purpose of this exercise is not to place blame, but rather to uncover a root cause. You can use this technique on its own, or as a part of a fishbone diagram (shown below).

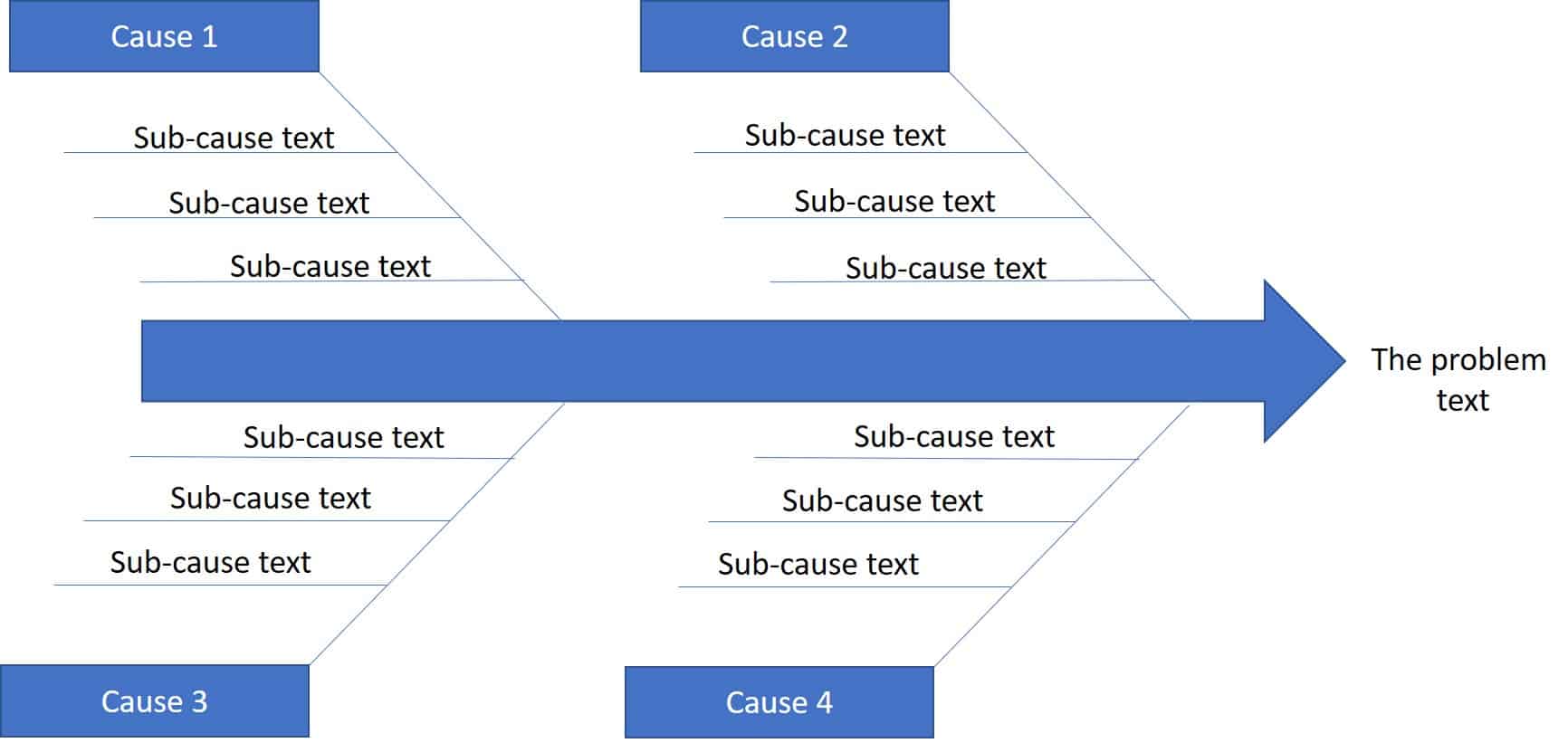

A fishbone diagram is a visualization tool helps you categorize all the potential causes of a problem so you can identify its root causes. The head of the diagram states the problem, and you can have many different branches for the causes.

In this example, you see four potential causes. Beneath each are the sub-causes. In this case, there are three for each cause, but these can range from one sub-cause to many. If you are using the five whys, choose which cause you want to start with on one of the fins and then ask the questions. In this example, “Method” was chosen for the first cause. You can see where to add the answers to your five questions. Fill in more fins to review all the plausible causes.

Download Fishbone Diagram Template — Excel

Swim Lanes

If you want to draw a single process map for the sake of simplicity, consider using swim lanes. As evidenced by the name, swim lanes connotate straight, narrow lanes of ownership. A part of Business Process and Modeling Notation (BPMN), swim lanes are a standardized way of looking at a process for who “owns” it, and where handoffs occur. BPMN is a straightforward, standardized language. There are hundreds of symbols that may be used, but the vast majority of professionals use only a handful. As you can see in the diagram below, the “Lanes” (or swim lanes) signify who owns that portion of the process and where the process dips to other owners.

To learn more about BPMN, see “Beginners Guide to Business Process Modeling and Notation (BPMN).”

SIPOC Analysis Diagram

A SIPOC analysis diagram looks at suppliers, inputs, processes, outputs, and customers to define your process. These five process definers head each of the columns in a SIPOC diagram, as specified swim lanes, and show how each interact. The process’ scope is clear with this diagram, and it offers a high-level view. Design your own SIPOC analysis diagram using the below free template in Excel.

Download SIPOC Analysis Diagram — Excel

Value Stream Maps

One aspect of Lean is value stream mapping, which is a way to to visualize the flow of materials and information as the product or service goes through its value stream. Every step of the process is accounted for in detail. The state that you start with is the as-is or current state, and you can use another model to develop your to-be or future state. In the example below, time is detailed for each step of a process.

What Are Process Improvement Measurement Techniques?

There are three main measurement techniques (financial results, an assessment tool, and a stakeholder’s opinion) to determine whether your improvement projects are successful. Before launching a project, you should have an obvious line of sight and measurement from your project to your outcomes. Any one of these may be used, but the best scenario is to include all three.

-

Financial Results: Organizations measure financial results in different ways. Whether this means short term cash flow generated on the balance sheet, or long-term profitability, recognize what profitable means for your company. Your improvement project should provide a line of sight from the improvement to the financial measure or key performance indicator (KPI). For financial measures specifically, take a systematic approach with a baseline, standardized data requirements and approved calculation methods. Ensure that you include any bespoke finance department personnel to sign off on your process to improve your credibility. From there, develop a surveillance system, including a tracking report, intervals for reporting, and a distribution list.

-

Assessment Tool: Most assessment tools boast a detailed and defined scoring technique that may be more qualitative in nature. The criteria for scoring must be meticulously annotated. Consistent scorers and documented techniques are recommended, with third party tie-breakers where necessary. The gold standard in qualitative data review is when you have two independent data reviewers compare their reviews and a third reviewer decides on any discrepancies. Improvements guided by assessment results are usually the most successful, as long as the professionals who perform this work are appropriately trained.

-

Stakeholders’ Opinion: Companies that consider their stakeholders’ needs and perceptions add to the long-term success of their business. There are many parties who have interest in your business, whether they are community, employees, board members, customers, or suppliers. Focus on the needs and expectations of these people in your long-term strategic plan to guarantee you will have a long term. In this way, you will measure the satisfaction and acceptance of your stakeholders when performing and measuring your improvement projects. Surveys, focus groups, assessments, and benchmark studies ensure you have the data to develop a direct line of sight to your stakeholders’ needs. A measure of success for any company is how key stakeholders view them.

From a change management perspective, measuring your initiative’s relative success can increase organizational awareness, drive further change, and reinforce the value and desire for improvement.

Process Improvement Organizations and Resources

Two main sources of process improvement materials, knowledge, and practices are the Lean Enterprise Institute (LEI) and the Lean Six Sigma Academy (LSSA). LEI is a nonprofit that researches, educates, and publishes Lean materials, collaborating with universities and other organizations to develop a wide network for Lean practitioners. Membership with LEI keeps Lean practitioners current with their practice and learning materials, and it offers them access to approved materials and other Lean professionals. If you want to get a certification with Lean, there are several programs you can pursue, although you do not need to be certified to practice Lean. SME has a program that is comprehensive in their concepts and offers various levels of training.

LSSA is a training academy for Lean Six Sigma practitioners. They are the Universal Certification Organization and Scheme Owner for Lean Six Sigma and offer training for each of the five belt levels of Lean Six Sigma, three belt levels of Lean, and an Automotive Engineer certification. The organization also provides training on other improvement methods such as Kaizen and TQM. This academy partners with other academies worldwide for consistent standards and offers tutoring.

Process Improvement Software

Software that supports your process improvement initiatives should be able to be used through every stage of development. Whether you are new to process improvement, are expanding your program, or are sustaining a thriving culture, software can help. Some organizations look for business process management (BPM) suites of software, and others prefer using in-house software that provides the tools needed to manage projects and provides some flexibility to choose their own path. If you want to have a large, comprehensive system, learn more about BPM here, as well as how to choose software for your company.

You can also review enterprise resource planning (ERP) systems, especially if your company is operations-focused. These solutions struggle with continuous improvement, but the software is rapidly improving. Quality management systems (QMS) seem like a natural choice for businesses that want to install continuous improvement programs. They are wonderful if you need ISO compliance, but they may not meet your operational needs. For more information on ISO requirements that prescribe using a QMS, see “The Ultimate Guide to ISO 9000.”

Most project management software includes features that can help you assemble good process improvement projects, using tools like Gantt charts, dashboards, and resource management without the strain of a large system whose purpose is to run all your operations. A good, lightweight solution should provide flexibility to manage initiatives, and respect how each of your leads performs their necessary functions.

Process Improvement and Healthcare

Healthcare is one of the most rapidly changing industries. Providing high-quality healthcare requires continuous improvement, and results in more lives saved and a better quality of care. The Institute of Medicine (IOM) mandated quality improvement in its report titled, Across the Chasm: Six Aims for Changing the Healthcare System. This report details how healthcare misses the boat when serving their patients and needs to change dramatically. This call to action asks healthcare to not only pay attention to stakeholders, but to constantly find ways to reduce waste and pass those savings onto patients. In other words, the healthcare industry needs to continuously improve their processes. According to IOM’s Committee on Quality of Health Care in America, a leading cause of death in the United States is a preventable adverse medical error. They expect that somewhere between 44,000 and 98,000 Americans die annually because of medical errors. Johns Hopkins estimates that more than 250,000 people die due to medical errors annually in the U.S.

As such, leaders in healthcare process improvement are tasked with a critical function: While in many industries, decreasing errors saves money and improves customer satisfaction, in healthcare, decreasing error saves lives. These leaders need many skills, the least of which is to be able to take the data they or their departments have gathered and operationalize it. Other requirements necessary for a successful process improvement leader in healthcare include the following:

-

Being embedded within the operation, but still reporting to the highest levels. This means that quality has its own identity in the organization, and as such is credible and taken seriously.

-

Being high enough within the organization to have influence, but autonomous enough to affect necessary changes based on employee feedback, regardless of the current administration.

-

Having access to the resources to affect change. The knowledge of how to go about challenging the current processes and make these changes is also critical.

-

Knowing the difference when system-wide change is necessary, as opposed to just department or hospital-specific change.

-

Having an executive sponsor who believes in, understands, and supports the intent of continuous process improvement.

The final requirement for healthcare process improvement leaders is to be the right leader, in the right place, at the right time. Healthcare systems need to be as perfect as possible. Leaders should use the tools available to meet this task. Collecting the right data, using that data in analytics, appropriately storing that data, and putting forth constant improvement beg the best person for the job. Below are the top required skills for a healthcare process improvement leader:

-

Communication: The people performing the work should understand the processes better than anyone else. They must also be able to share that knowledge and effectively understand their challenges, ideas, and knowledge. Build trust by being honest, open, and listening well.

-

Build Trust: For people to trust the improvement leader, they must feel heard and have buy-in to changes. Whether or not they can see the future, it is absolutely a requirement to help them understand the vision and have their backs.

-

Coach: Coaches help teams and individuals move from their current state to the vision they have for the future state. To do so, they must build their self-esteem, so they believe in their own abilities, but also provide them with real feedback so they know where to push harder for improvement in themselves.

-

Understand Process Management: To make improvements, professionals should fully understand the “as-is” workflows, including the steps, inputs, outputs, and required resources. From this, you can develop the “to-be” process. Further, collecting the right data can help create that future state by showing the root cause of the problem. Data sets your fixes apart from mere guesswork.

-

Understand Healthcare Personnel: Healthcare is a tough, fast-paced environment. It is all well and good to have a theory, but theories can fall apart in the real world. Therefore, it’s imperative to give healthcare staff the respect and latitude to do their jobs and effective assistance to improve their performance. Without their buy-in and expertise, you will never get the fixes you need to save lives.

-

Ensure Constructive Conflict and Accountability: The atmosphere that you create is critical to the personnel’s success. Cultivate an environment where conflict is okay, but it should be respectful, helpful conflict, rather than nasty, useless conflict. The difference is an openness and respect for each other (and yourself). While the historical information is important, the developed perspective makes the future a zero-defect state. Further, everyone is held and holds everyone else accountable.

-

Have Resilience and Persistence: The adage “Rome wasn’t built in a day” refers to the need for time to create remarkable things. Staff need to understand that changes are continuous, and it often takes time to see results. Further, sometimes things are challenging and do not work immediately. Keep the faith that change for the better can happen. Change management principles are your friend.

-

See the Big Picture: While in the thick of change and details, do not forget to constantly check the big picture for guidance. This is where your executives and executive sponsors come in handy to make sure that staff are keeping their big-picture vision in sight.

Finally, process improvement leaders in healthcare should have some formal training. The business of process improvement is a science, after all, and the concepts may be taught. Experience is the best teacher in how to apply this science and training, but they must start somewhere. All the tools, techniques, and methodologies found in this guide are a good place to start.

The Process improvement Plan

Successful process improvement never comes about accidentally. Behind each success is a solid plan, meticulously developed and executed. A process improvement plan is the steps you follow to cover all your process improvement bases and needs. To succeed with a process improvement plan, keep two main ideas in mind: involve staff early and make processes local where possible. Then, you need to do the following:

-

Understand the way your company communicates about its work.

-

Choose a methodology to work with during your process improvement.

-

Commit to continuous improvement.

To get these three things accomplished, you must think through some groundwork:

-

Link all processes to your company’s strategic plan using a process hierarchy, which is a map that fits all your processes together to show a high-level business model. Identify an owner for each process.

-

For each process map, identify who else is affected by the process.

-

Develop a procedure to ensure that each process happens and is reviewed.

-

Make sure you have continuous improvement by following up on any issues with analysis.

-

Develop documentation standards. Documentation, not tribal knowledge, helps ensure improvements are maintained.

Now, you can follow these steps to developing a good process improvement plan.

- Choose a Process Collaboration Tool: There are many software suites and cloud-based tools available to help document your process. First, understand what will work for your disparate staff. Look for a tool that will encourage usage, coordination, and flexibility. Your staff will necessarily have different technology capacity levels. The following are your criteria for a starting point:

- Accessible and shareable

- Collaborative

- Mobile-friendly

- Online

- Integrates with other tools

- Multiple functionality

- User-friendly

- Functional, yet simple

- Develop your process hierarchy and procedures. The process hierarchy is an overview of all your processes and how they are linked together. The procedures are how you want these processes created, when necessary. Taken together, this documentation ensures that your staff can create processes where needed, while staying consistent and apprised of required information.

- Identify the process owners. Process owners are internal staff whose knowledge and expertise make them appropriate owners. These people are the informal leaders in your company. Make sure each owner understands their role and requirements, and develops and applies a training protocol. Provide some mapping and instruction writing training. HR should track these ownership roles.

- Develop company-wide communications. If the processes you have mapped out affect the entire company, then the whole company should understand changes are happening. Process owners should be identified to the whole company, so they can affect change when needed with their colleagues’ support.

- Develop the process flow charts. At this point, your process owners have all the pieces in place to develop the full flow charts. Map out the “as-is” of your processes step by step before you consider ideas of “to-be.” Consider having an outside entity, whether a consultant or an executive manager, to initially support this process owner. After you develop the first draft, run it by all the staff with knowledge of its current exists.

- Run your processes as they are mapped out. This step, usually left out of process mapping, ensures your documentation and your reality match. Process mapping is considered stabilizing the processes. During this step, identify any problems, bottlenecks, or issues that arise and run them by the staff involved for their opinion and feedback. At this point, you should have a list of potential improvements.

- Improvement: Implement improvements where necessary and realistic. Some improvements may happen slowly over time due to any problems’ complexity. Some are easy fixes. To sustain the improvements, consider implementing a compliance dashboard that the quality manager can regularly review and audit. Develop intervals and a regular routine for process improvement work.

For more information on improvement plans, to develop your own improvement plans using free Word templates, and to see sample improvement plans, see “Performance Improvement Plan Templates.”

How to Run a Process or Service Improvement Workshop

Many experts recommend not just leaving process improvement to the process owners to develop intervals for improvement. Said another way, you can and should consider having scheduled events or workshops for process improvement away from regular work. The length of these events or workshops can vary based on how many processes you are hoping to improve at once and the complexity of the issues. You could also designate one day per month or a few days in a row for the workshop. To get started, follow these steps:

-

Set Up: Determine which processes to review, who should attend, whether you need an executive sponsor, what you will communicate ahead of time, event logistics, and what the staff need to know about expectations and the process(es). Any collected data about the processes needs to be available to the event. Also, plan for people who may need to observe the process in action before the event.

-

Show the “As-Is:” Whether you show this on brown paper or with a complex software program, you must share the entire process to your participants, so they can fully grasp what they are seeing. They will also want to know what happens just before and after the process they are reviewing. Ideas that come up during the review should be written down and parked. This review should look for waste and opportunities for improvement, as well as any constraints, such as functional requirements.

-

Redesign: This is the “to-be.” Taking any customer feedback first, redesign your process(es). Begin where the “as-is” starts and make certain the principles of the process are fully clarified. Ask whether each step delivers on its purpose. Capture any new actions and any necessary owners or owner changes. Compare the before and after process. Draw out the steps, handoffs, time, and possible errors.

-

Get Agreement: Making sure the whole team is present, post the “to-be” process, and review whether the issues were addressed, stressing any affect the new process has on its metrics. If you have full support, move to close the event. If not, you could always have a recurring event.

Related Process Improvement Topics

The following are brief overviews of topics related to process improvement meant to expand your interest and knowledge around process improvement:

-

How Robotic Process Automation Can Improve Businesses: Robotic process automation (RPA) is the automation of processes using software robots or artificial intelligence (AI). Companies specializing in RPA or turning to RPA for automation cite exponentially increased efficiency and accuracy of back-end work processes that take the onus off humans for the completion of routine, rote work. Many businesses have improved not only their bottom line, but also their staff satisfaction by giving humans more challenging tasks.

-

Robotics Technology and Workflow Automation: Some experts cite cost savings up to 300 percent when implementing RPA to drive their workflows. Robotics technology uses AI and machine learning to improve the ROI and continuous process improvement.

-

Metrics to Measure DevOps Business Improvements: DevOps is a blended term for software development and information technology operations, with the goal of making the software development cycle shorter and better aligned with the company’s operations. Some metrics to measure how good your DevOps is running are lead time, deployment frequency, customer tickets, and automated test pass percentage.

-

Performance Management Software Improves Company Performance: As any recruiting company can tell you, tracking performance is critical to success. Sales leaders will also pontificate on the success rate of their high performers and how they track them. There are multiple software programs on the market to help perform this tracking. Even though you may only be tracking a portion of your staff, this activity can show a net improvement for your whole company by making staff’s needs and linkages transparent.

-

Four Clinical Teams Needed to Drive Sustainable Improvement: In the healthcare industry, where continuous improvement saves lives, you need four teams to ensure success. These include your leadership team, a clinical expertise team, a front-line team, and the improvement workgroup. To affect real change, these teams must consider best practices, collected analytics, and best adoption mechanisms.

-

Six Steps for Improvement in Healthcare: More complex and serious than almost any other industry, healthcare must be approached in a methodical manner. In order to make real change, improvement professionals must combine performance improvement with program improvement, use appropriate data analytics, determine the change readiness and level of change management tactics necessary, identify permanent improvement teams, identify clear goals that align with evidence-based practices, and develop estimated project ROIs.

-

The Five Deming Principles for Healthcare Improvement: Instead of reinventing the science of process improvement, healthcare professionals should take advantage of years of theory development. Dr. Edward Deming developed the following five principles for process improvement. Here they are worded for healthcare:

- Quality improvement is the science of process improvement.

- If you cannot measure it, you cannot improve it.

- Managed care manages care processes, not the care professionals.

- Use the right data.

- Engage the clinicians.

-

Three Teams to Sustain Healthcare Quality Improvement: Changing the structure in your healthcare organization can help sustain quality measures, enthusiasm for improvement, and accountability. These include a clinical implementation team, a clinical workgroup, and a senior executive leadership team.

-

How to Be Successful with Healthcare Improvement Initiatives Using Key Staff: Buy-in from your healthcare staff can make or break your improvement initiative. This being the most difficult of tasks, however, you need to choose the right staff to influence the rest of the team. These team members are called influencers and should be on at least one of three of your clinical teams — all but your leadership team for improvement. Choose these people carefully for the respect they garner within their profession and workplace.

Build Powerful, Automated Business Processes and Workflows with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.